The Engine that Stopped the world!

Mood:

happy

Topic: RadMax

happy

Topic: RadMax

History of First Generation Prototypes

October 31, 1982 development of prototypes begin in Pakistan. Several prototypes built but none achieve "successful technical operation" as specified in contract with Sarhad Development Authority. Reasons for failure of prototypes were; low quality wrought iron, imprecise machining tolerances, incorrect machining procedures, and impact loading of vane and cam.

In 1985 a prototype was built in Canada by Universal Machining and Engineering. This prototype also didn't achieve "successful technical operation". Reasons for failure were incorrect machining procedures and impact loading of vane and cam. The color picture of the Rand Cam-Engine is an example of the first generation engine. This engine had sufficient compression but only operated for several minutes, hardly a working engine.

History of Second Generation Prototypes

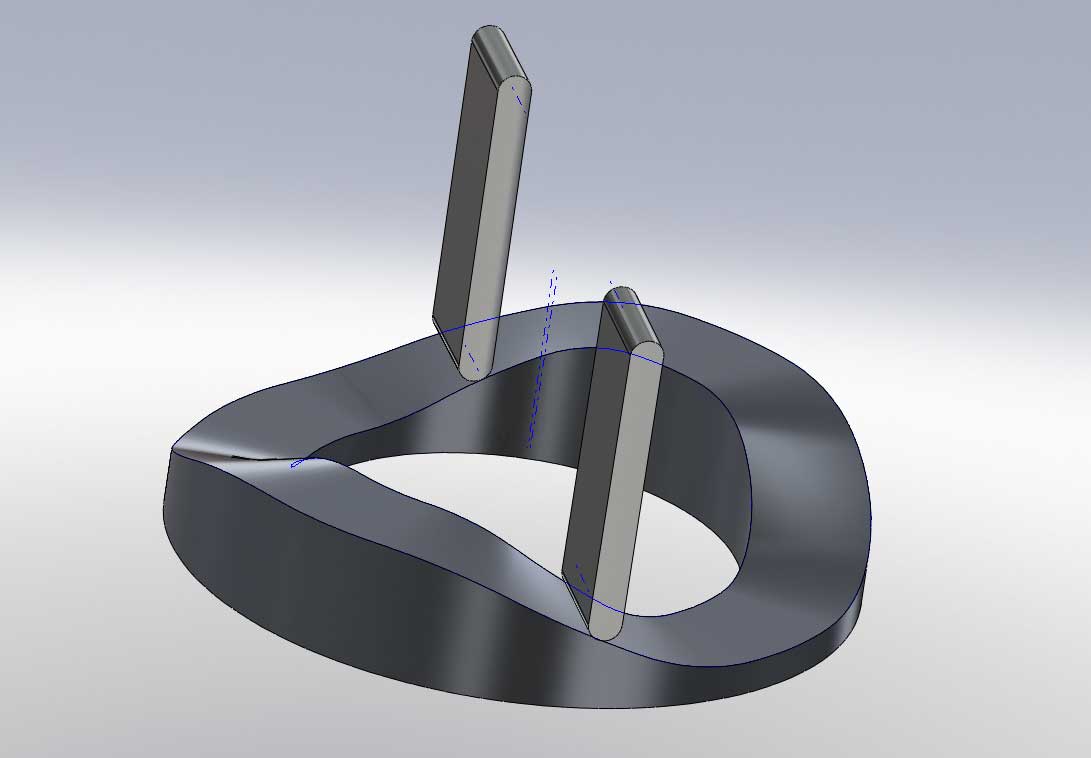

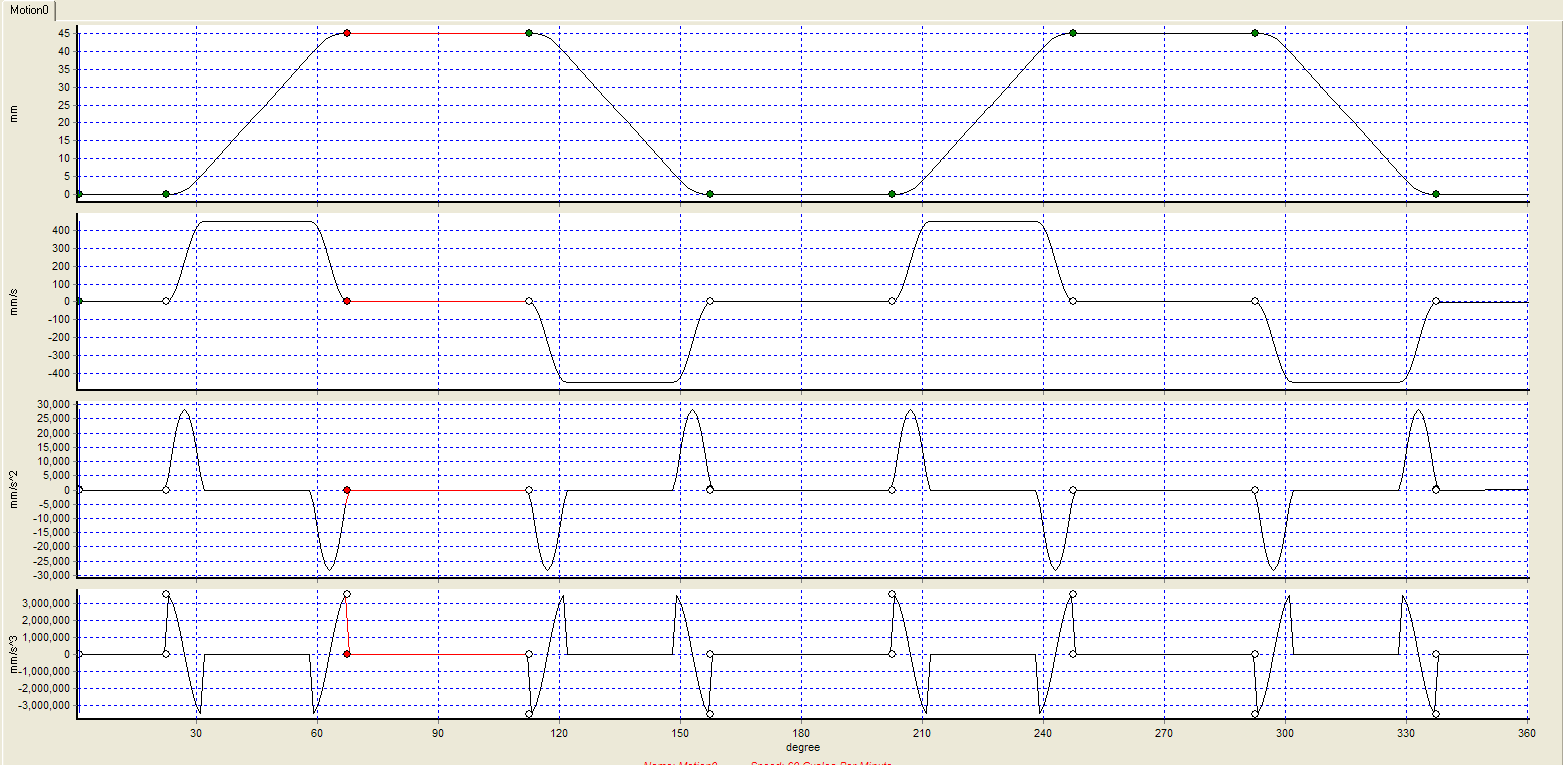

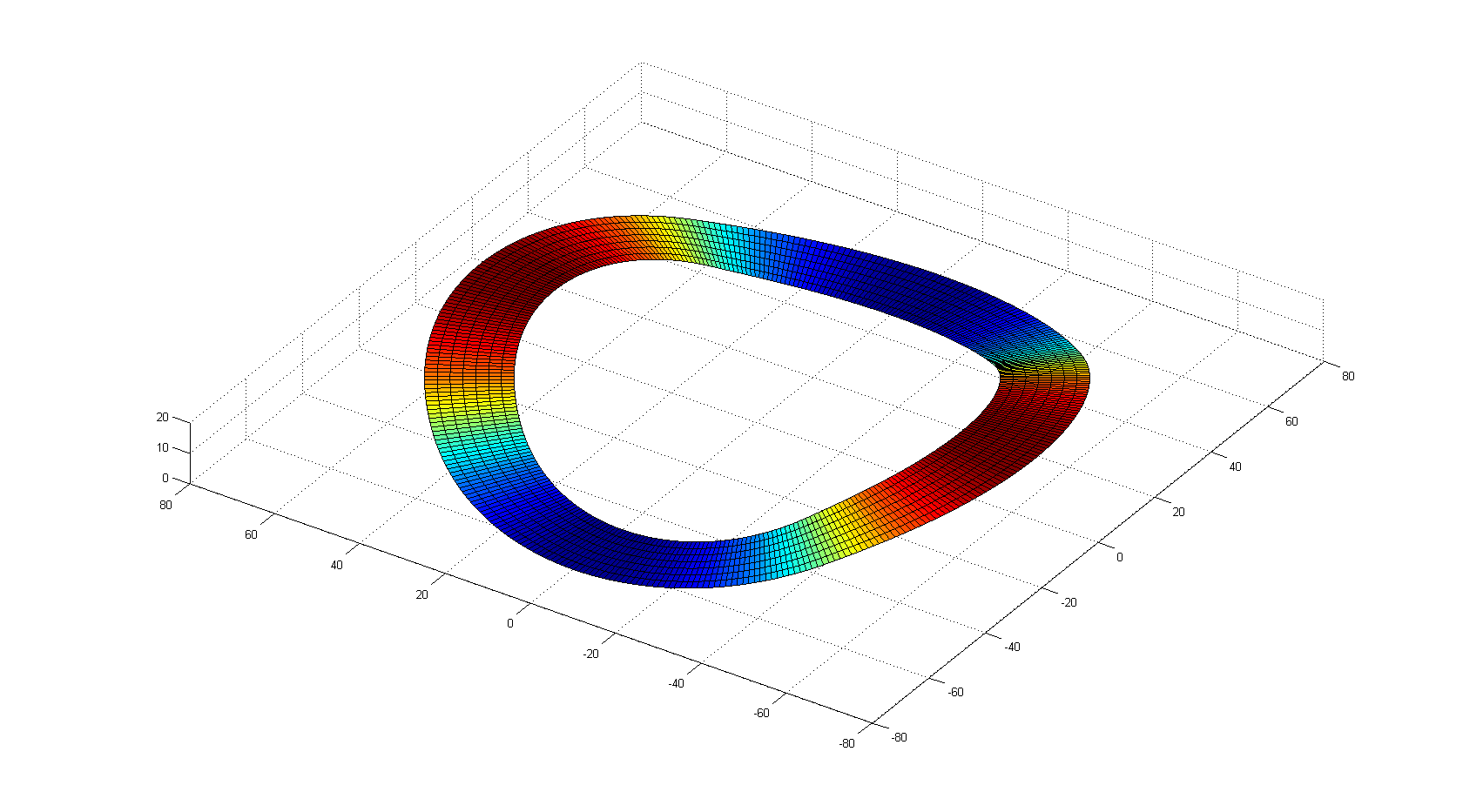

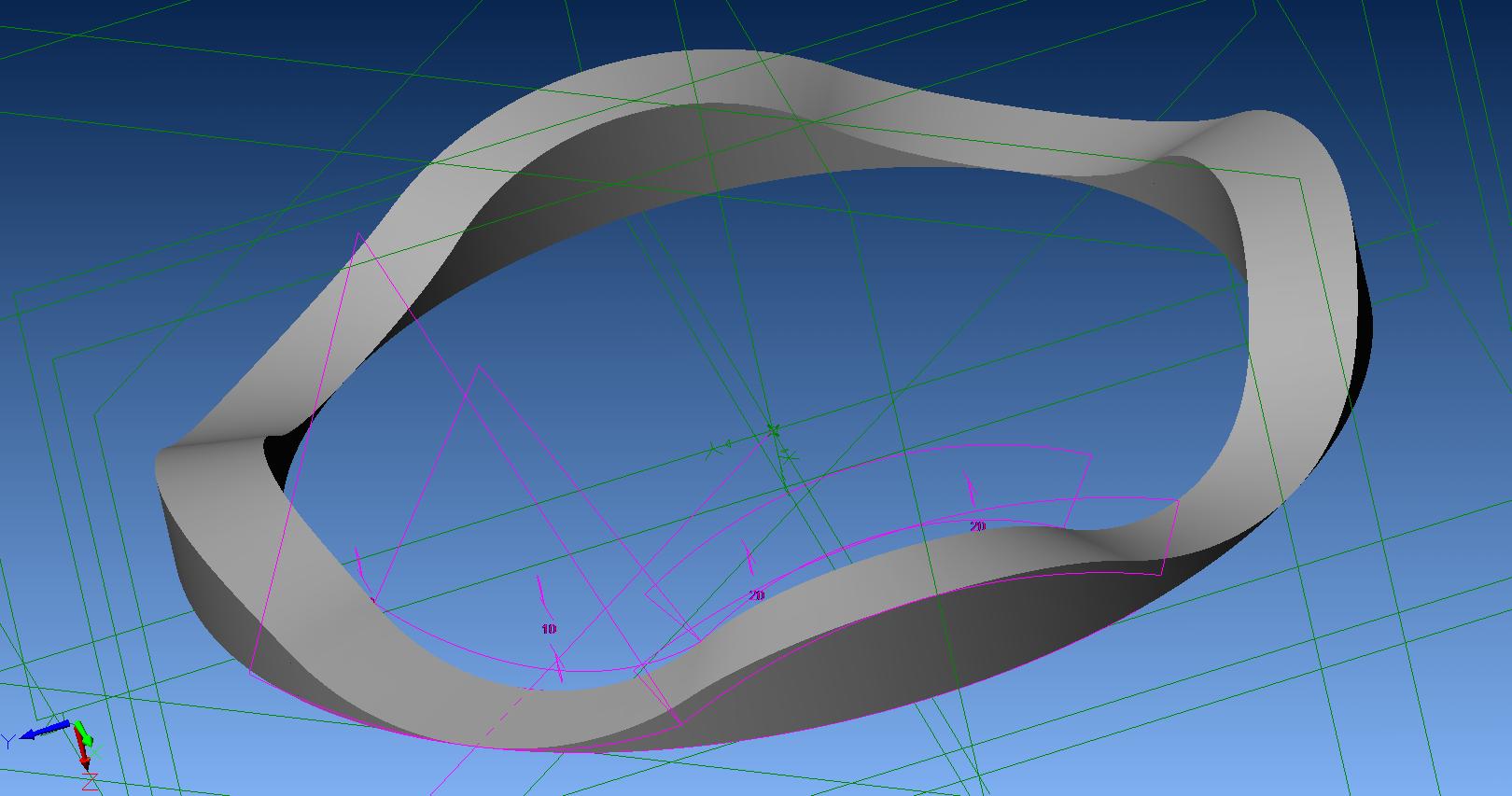

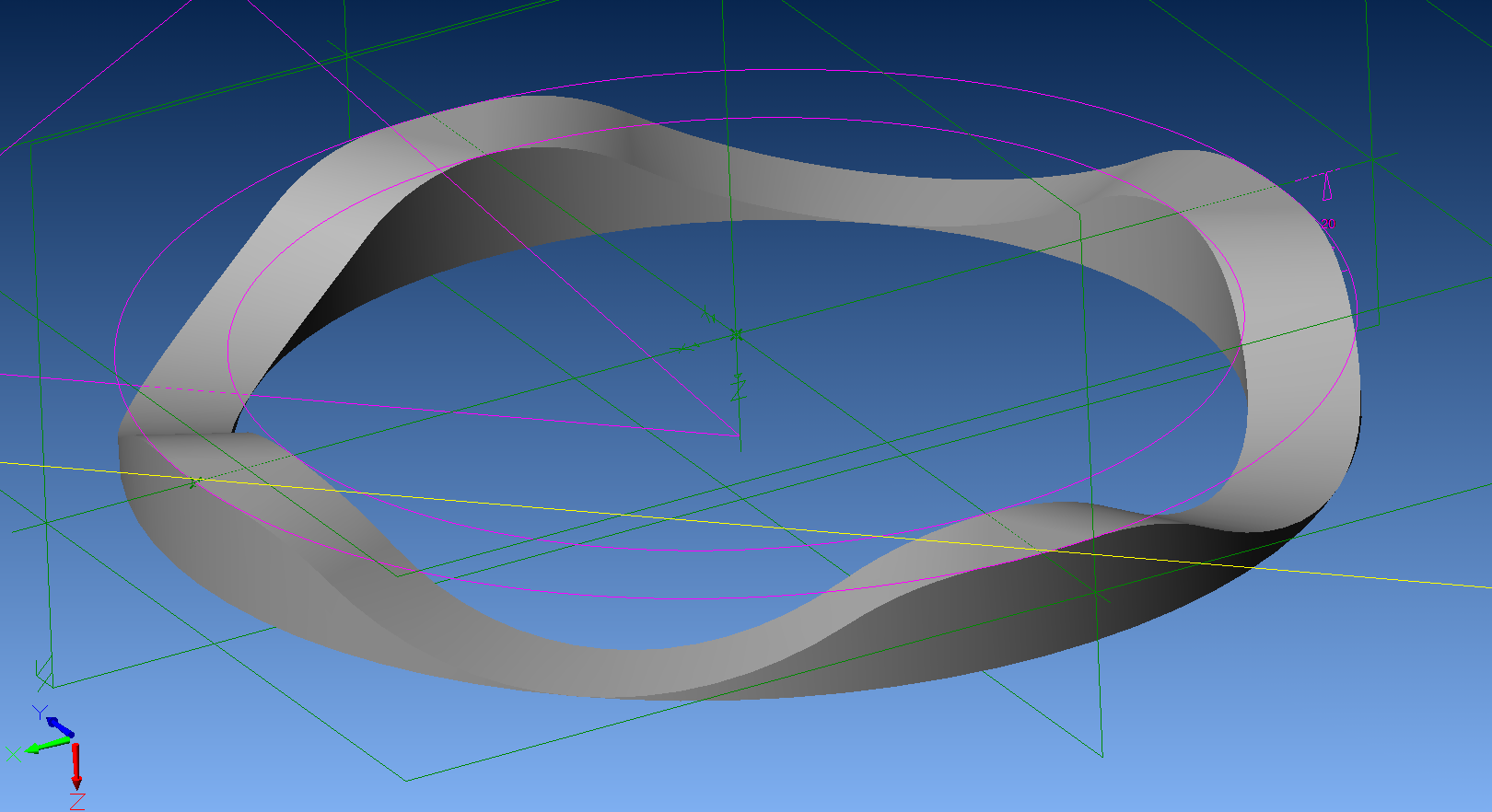

This generation of engine incorporated a transition area on the Cam that allowed for a smoother change in direction. It was redesigned to eliminate the impact loading of the vane and cam. Also Devron Hercules was contracted to use its Computer Numerically Controlled Machine tools to machine the new cam design. However Devron Hercules gave up after two weeks, their programmers said that cutting the new cam profile was mathematically impossible. Dale Robinson (dbrobinson (at) hotmail.com) reviewed the programming problem and provided a valid programming solution. Devron Hercules then cut the new cam design on their CNC machine tool. The new cam was verified as correctly machined and installed in the engine. The new design lasted five minutes of operation and then failed. The reason was impact loading at the same location on the cam. The cams were redone and then ion nitrided to harden the surface. The engine operated for ten minutes then failed. Inspection revealed impact loading at the same location and Dale Robinson could have warned James McCann the inventor and the engineering team that the Cam Profile was incorrect. However there was no contract involved in providing the correct cam profile so that information was withheld from the development team. The correct cam profile and timing of the Rand Cam Engine is outlined in this report and can be mathematically proven by a qualified engineer.

Third Generation Engine Prototype The University of West Virginia totally redesigned the Rand Cam-Engine and proceeded with their development effort. There redesign radically changed the theory of operation of the Rand Cam-Engine. Specifically four vanes were added and the vane tip was rounded off. This translated into only 60 degrees between each vane. This means that there is no 45 degree pauses at the intake and exhaust stroke.

Also since the power stroke is greater than 60 degrees there is a substantial amount of overlap between power strokes. This means that the engine begins to work against itself. Present estimates of fuel efficiency of this new design is about 70 mpg. University of West Virginias' design clearly violates the original concept and has severe sealing problems because of these changes.

Fourth Generation Prototype

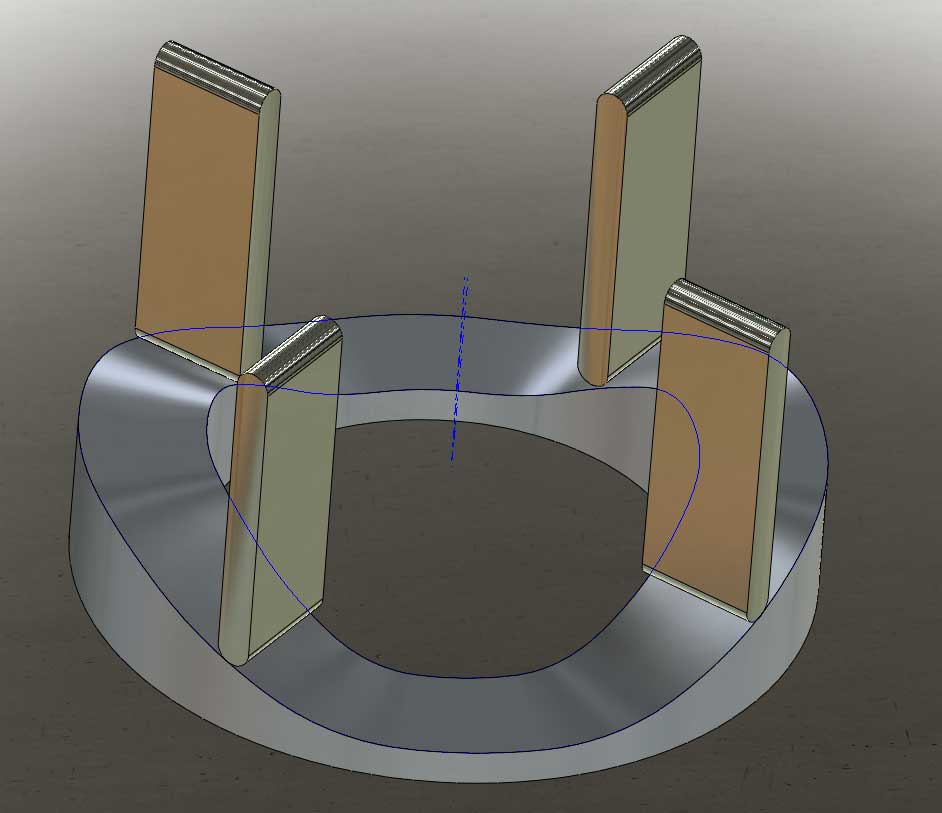

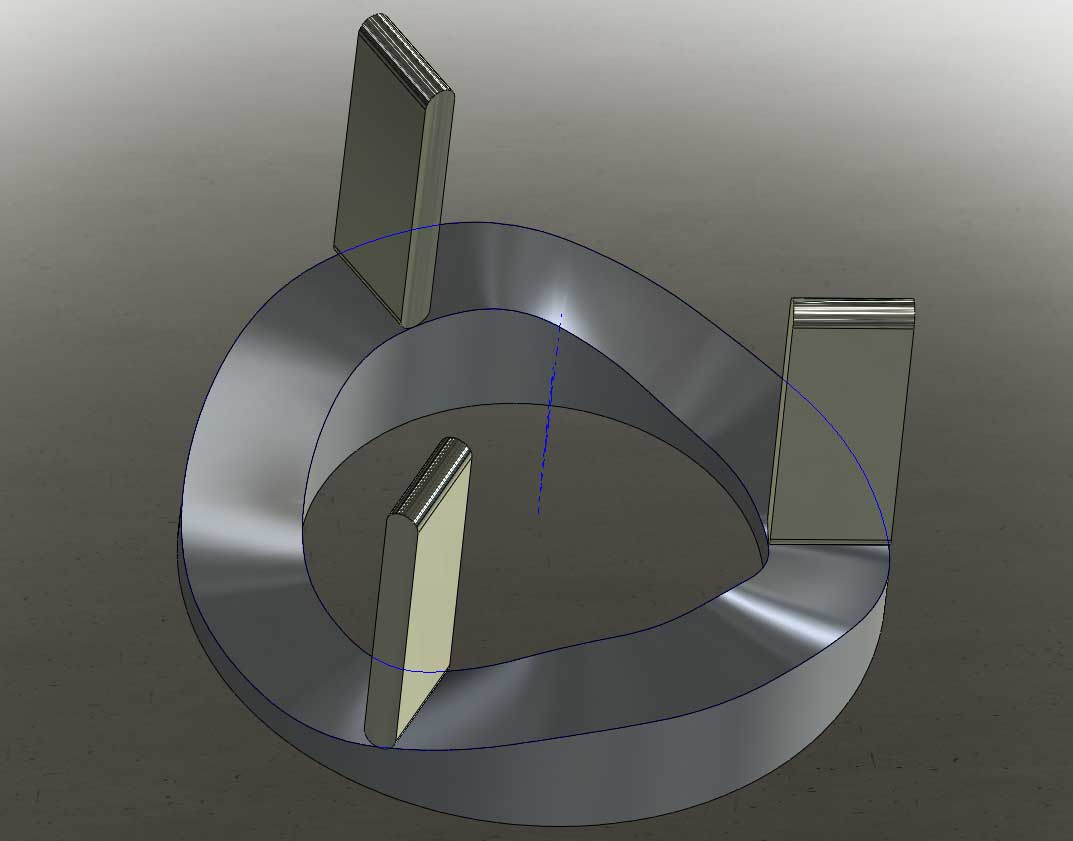

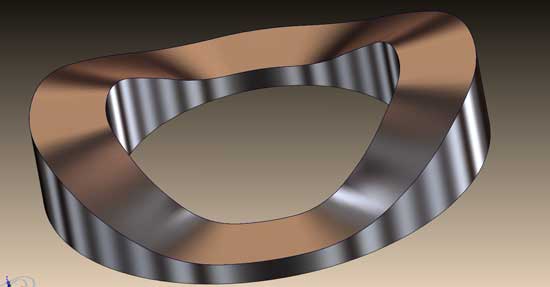

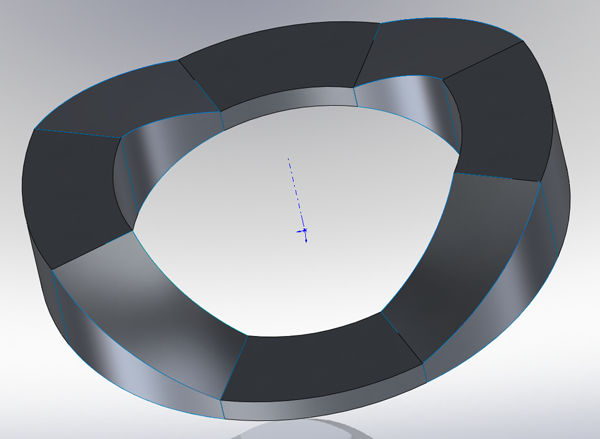

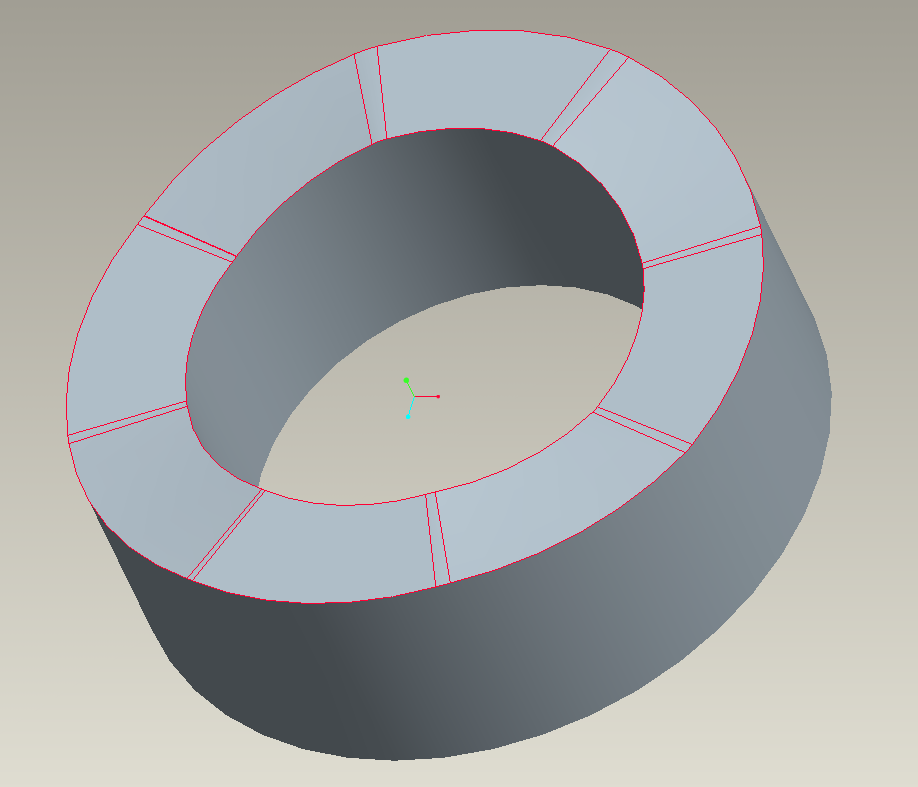

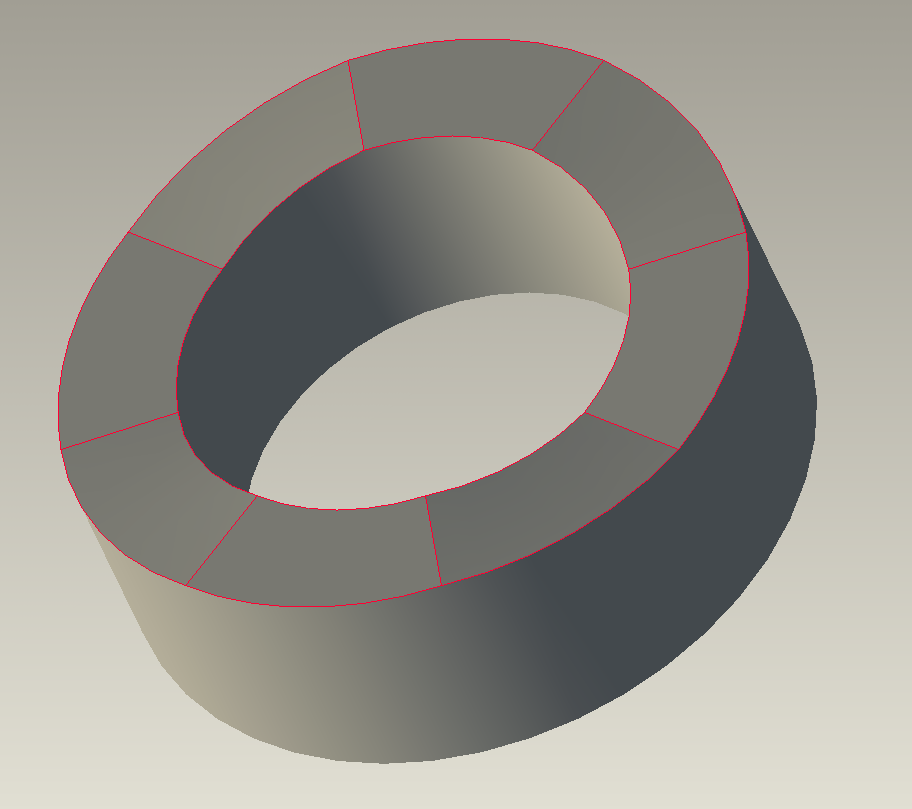

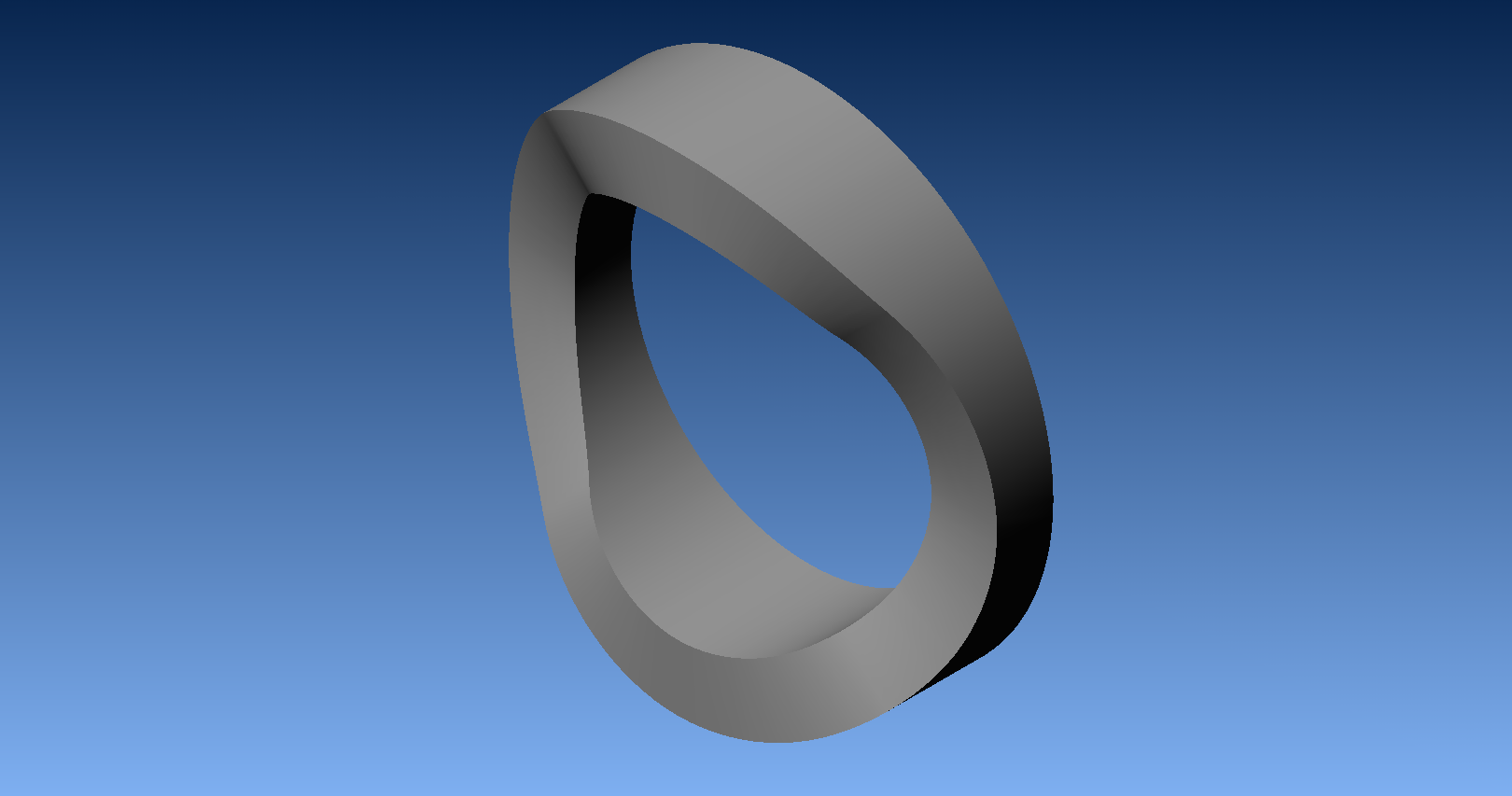

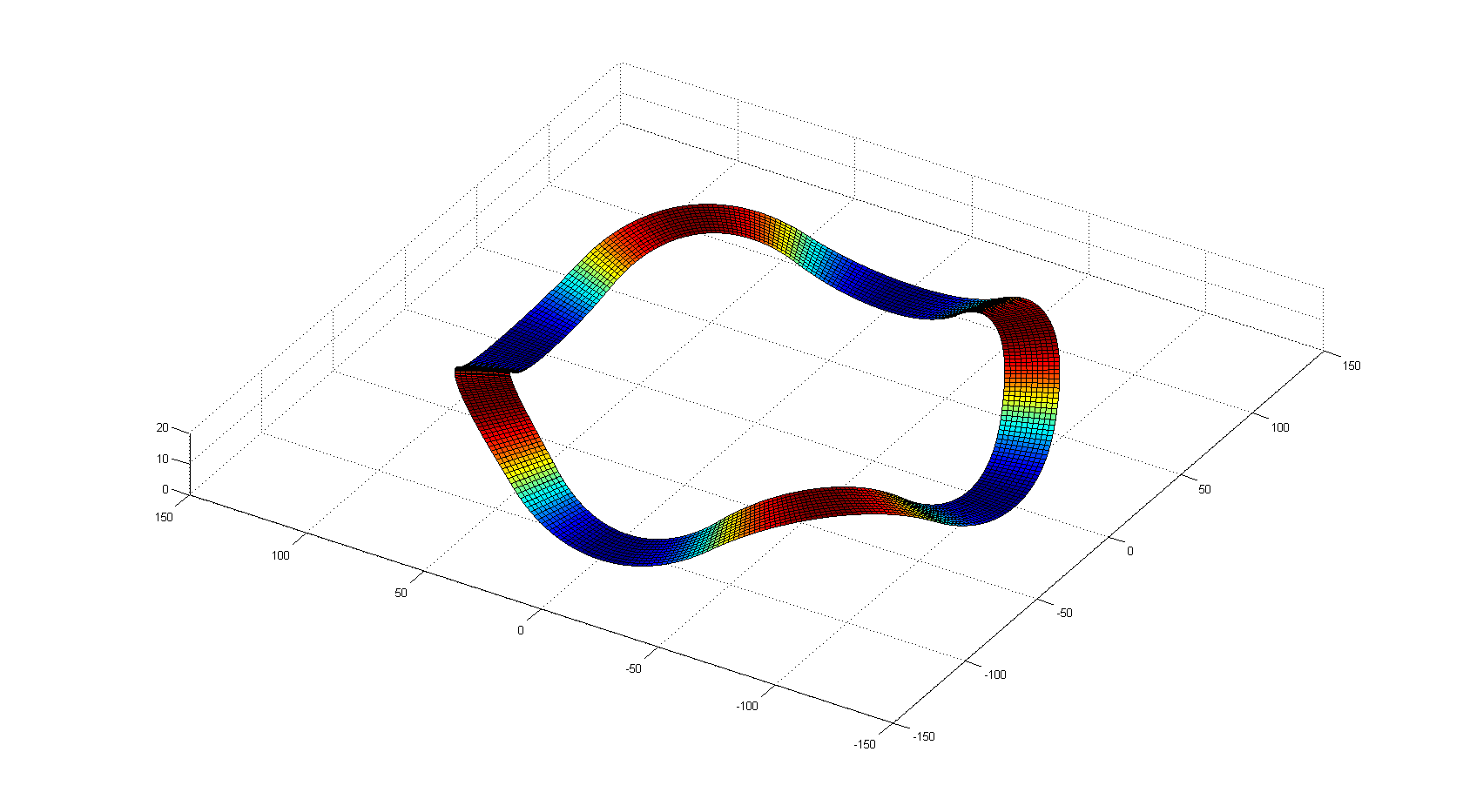

The RadMax™ engine is also based on the four-stroke "Otto" cycle. However instead of requiring two complete revolutions of the crankshaft to process the “Otto” cycle’s four strokes (Intake, Compression, Power, and Exhaust), the RadMax™ engine implements Rand Cam™ Diesel engine technology. This means that it is a positive displacement, compression ignition machine that consists of a rotor with multiple axial vanes. These vanes form combustion chambers as the rotor and vanes rotate in a cam shaped housing. The cam housing is referred to as a stator, which contains a toroidal trough of varying depth machined into each stator.

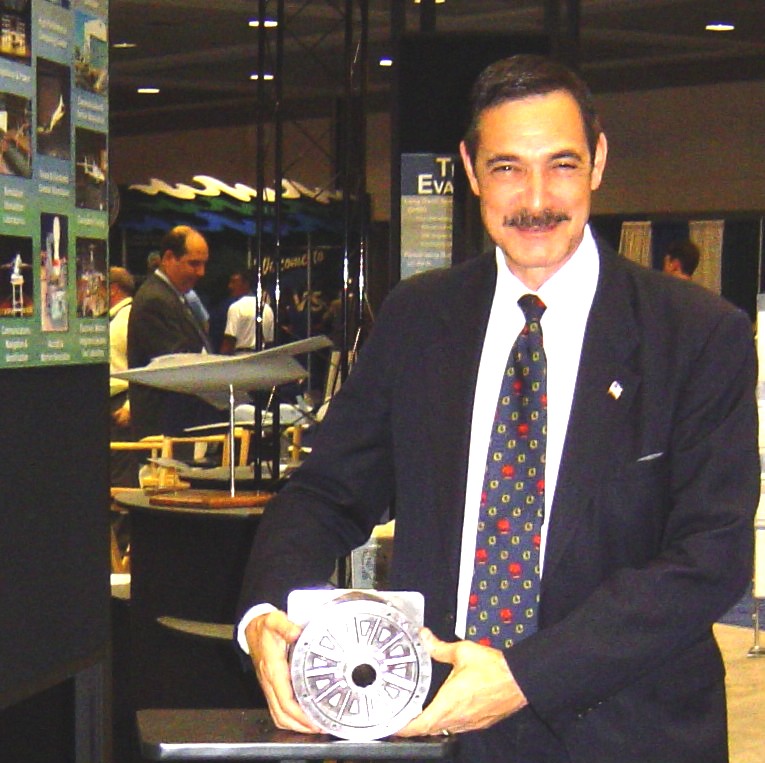

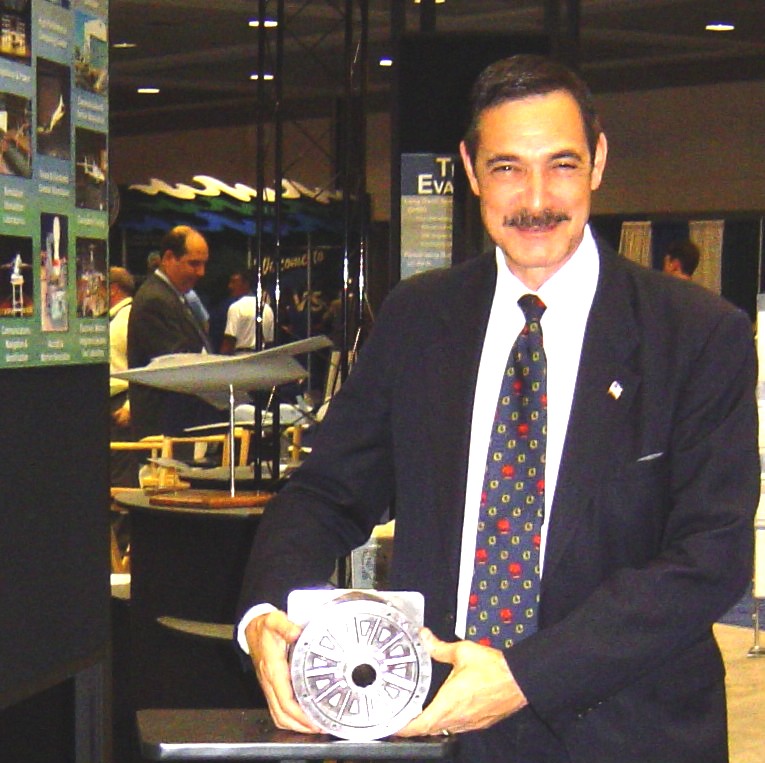

"This engine is a technological breakthrough!" a particular German viewer was overheard to say. How much of a breakthrough? Well it's been almost 20 years in development, but until Radian MILPARTS accepted the challenge to finish the development, it basically was just a dream. A dream of many, many folks. But now it's a reality.

Radian took down their RadMax site because of concerns from Tony Cuthbert, because the RadMax is very similar to his turbine design.

I had read some articles regarding Watchtower owns the Rand Cam Engine and actually got a call from some one interested in finding out more about this. I had left my phone number on an online resume at Tripod, I thought it was to talk about the engine but it was to stir up trouble. My take on the situation is that Jim made a promise to himself that he was going to put a percentage of the RCE into trust for the Watchtower. However if you ask the Watchtower if they got any money when Jim sold out to RegTech ---i doubt it...

I read the Watchtower's press release on the matter and was sort of honored that they mentioned two brothers were developing it and they had nothing to do with the Rand Cam Engine.

I tried to get into meaningful conversations with investors that put money into the RCE but was called all sorts of names. So now I just watch RegTech try pump up their stock prices, from a distance.

I was hoping to talk to Rob Grisar from Radian about making the RadMax a viable design but he got gunshy after Tony Cuthbert's lawyer got hold of him I guess.

Archived RadMax webiste

http://www.radmax.easyitis.net/

Cuthbert Turbine

http://www.cuthbert-physics.com/hybridTurbine.html

Posted by sharpshooter6543210

at 12:46 AM PDT

Updated: Tuesday, 18 September 2007 2:15 PM PDT